Introduction: The Warping Nightmare

When Boeing engineers first 3D printed ABS aircraft components, they faced a 47% scrap rate due to warping. Today, advanced techniques have reduced failures to under 5%—and you can achieve similar results.

This guide reveals proven methods used by aerospace labs and hobbyists alike to conquer ABS curling, from basic fixes to cutting-edge solutions.

Why ABS Warps: The Science Behind the Curl

ABS (Acrylonitrile Butadiene Styrene) shrinks 1.5-2% during cooling, creating internal stresses that lift edges.

Key factors:

| Factor | Impact Level |

|---|---|

| Bed Temperature | ★★★★★ |

| Ambient Drafts | ★★★★☆ |

| First Layer Adhesion | ★★★★☆ |

| Print Speed | ★★★☆☆ |

“Think of ABS like a pizza crust—cool it unevenly, and it curls up,” explains Dr. Lena Kowalski, materials scientist at 3D PrintTech Labs.

7 Proven Methods to Stop ABS Warping

1. Bed Preparation: The Foundation

Optimal Setup:

- Surface: PEI sheet (textured) or Garolite (for high-temp ABS)

- Adhesives:

- ABS slurry (ABS scraps + acetone)

- Magigoo ABS (applied at 110°C)

- Temperature: 100-110°C for the first layer, 90-100°C thereafter

Pro Tip:

“Clean your bed with acetone, not IPA—ABS bonds better to chemically etched surfaces,”

— MarkForged Application Engineer, Ryan Chen

2. Enclosure: Non-Negotiable for ABS

Minimum Requirements:

- 40°C internal temperature

- Polycarbonate panels (withstands 120°C)

- Silicone gaskets for door seals

Budget Hack: Use a cardboard box with Kapton tape (works up to 80°C).

3. First Layer Settings: Make It Stick

| Parameter | Ideal Value |

|---|---|

| Nozzle Temp | 240-250°C |

| Bed Temp | 105-110°C |

| Speed | 15-20 mm/s |

| Line Width | 150% nozzle diameter |

| Z-Offset | 0.05mm squish |

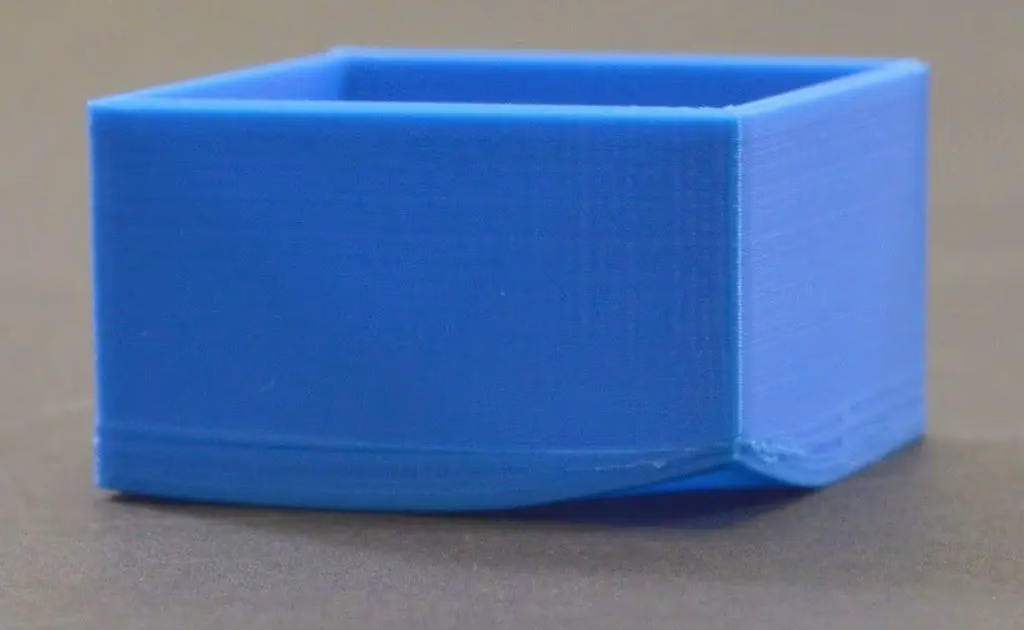

Visual Check: Your first layer should show slight flattening without transparency.

4. Brims & Rafts: When to Use Each

- Brims: 8-15mm width (best for large flat parts)

- Rafts: 3mm base + 1mm interface (for small contact areas)

- Mouse Ears: 5mm discs at corners (alternative to full brim)

CAD Trick: Add anti-warping tabs in Autodesk Fusion (2mm thick, 10mm wide).

5. Temperature Control: Beyond the Bed

Advanced Solutions:

- Chamber heater: Maintains 50-60°C ambient

- Nozzle sock: Prevents part cooling from hotend

- Draft shield: 2-wall perimeter around print

Industrial Approach:

Stratasys FDM machines use active chamber heating at 75°C for zero-warp ABS.

6. Filament Management: Often Overlooked

- Dry ABS: 4hrs at 80°C (wet filament warps 30% more)

- Brand Matters:

- Low-warp ABS: Polymaker ABS+ (0.8% shrinkage)

- Industrial-grade: Sabic MG94 (used in automotive)

7. Design Adjustments: Engineer Out Warp

- Fillet edges: 3mm radius reduces corner stress

- Uniform wall thickness: Avoid transitions >2mm

- Orientation: Print tall parts vertically

Troubleshooting Warped Prints

Salvaging Warped Parts

- Heat Gun Method: Gently reheat and clamp flat

- Acetone Vapor Bath: 30 sec exposure + weighted press

- Milling: Trim warped base on CNC (for functional parts)

ABS vs. ASA: Warping Compared

| Material | Shrinkage | Warp Risk | Best For |

|---|---|---|---|

| ABS | 1.5-2% | High | Automotive interiors |

| ASA | 1.2-1.6% | Medium | Outdoor applications |

| ABS+ | 0.8-1.2% | Low | Prototyping |

“ASA is my go-to for large prints—it warps less but sands worse than ABS,”

— Prototyping Lead, SpaceX Engineering Team

FAQ: ABS Warping Solutions

Q: Can I print ABS without an enclosure?

A: Only for tiny parts (<5cm). Larger prints will warp 90% of the time.

Q: Why does my ABS warp after 10 layers?

A: Top layers cool too fast—increase chamber temp or reduce fan speed.

Q: Best cheap enclosure for Ender 3?

A: Creality’s $60 tent (maintains 45°C with bed heat).

Q: Does glue stick work for ABS?

A: Poorly—use ABS slurry or specialized adhesives like Layerneer.